電液動漿液閥產(chǎn)品概述

電液動漿液閥產(chǎn)品概述 技術(shù)參數(shù)范圍

技術(shù)參數(shù)范圍 電液動漿液閥優(yōu)點

電液動漿液閥優(yōu)點 Product introduction

Product introduction Technical Parameter Range

Technical Parameter Range Electric hydraulic characteristics of slurry valve

Electric hydraulic characteristics of slurry valve

|

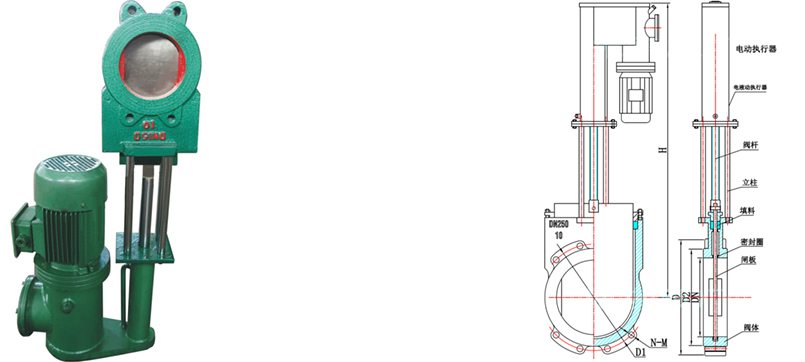

主要外形及連接尺寸Profile and connection dimension 主要外形及連接尺寸Profile and connection dimension |

單位Unit:mm 單位Unit:mm |

||||||||||||||

| PN | DN | L | D | D1 | D2 | H | N-M | PN | DN | L | D | D1 | D2 | H | N-M |

| 0.6 | 50 | 40 | 125 | 100 | 90 | 302 | 4-16 | 1.0 | 50 | 40 | 125 | 100 | 99 | 302 | 4-16 |

| 65 | 40 | 145 | 120 | 100 | 317 | 4-16 | 65 | 40 | 145 | 120 | 120 | 317 | 4-16 | ||

| 80 | 50 | 160 | 135 | 125 | 340 | 4-16 | 80 | 50 | 160 | 135 | 135 | 340 | 4-16 | ||

| 100 | 50 | 180 | 155 | 145 | 378 | 4-16 | 100 | 50 | 180 | 155 | 155 | 378 | 4-16 | ||

| 125 | 50 | 210 | 185 | 175 | 430 | 4-16 | 125 | 50 | 210 | 185 | 185 | 430 | 4-16 | ||

| 150 | 60 | 240 | 210 | 200 | 528 | 4-20 | 150 | 60 | 240 | 210 | 210 | 528 | 4-20 | ||

| 200 | 60 | 295 | 265 | 255 | 620 | 4-20 | 200 | 60 | 295 | 265 | 265 | 620 | 4-20 | ||

| 250 | 70 | 350 | 320 | 310 | 771 | 8-20 | 250 | 70 | 350 | 320 | 310 | 771 | 8-20 | ||

| 300 | 70 | 400 | 368 | 362 | 875 | 8-20 | 300 | 80 | 400 | 368 | 375 | 875 | 8-20 | ||

| 350 | 80 | 460 | 429 | 412 | 982 | 10-20 | 350 | 90 | 460 | 429 | 435 | 982 | 10-20 | ||

| 400 | 80 | 515 | 482 | 462 | 1245 | 10-22 | 400 | 120 | 515 | 482 | 485 | 1245 | 10-22 | ||

| 450 | 90 | 565 | 532 | 518 | 1338 | 14-22 | 450 | 120 | 565 | 532 | 545 | 1338 | 14-22 | ||

| 500 | 100 | 620 | 585 | 568 | 1465 | 14-22 | 500 | 130 | 620 | 585 | 609 | 1465 | 14-22 | ||

| 600 | 100 | 725 | 685 | 670 | 1658 | 14-27 | 600 | 140 | 725 | 685 | 720 | 1658 | 14-27 | ||

| 700 | 100 | 940 | 800 | 775 | 1900 | 16-27 | 700 | 140 | 940 | 800 | 788 | 1900 | 16-27 | ||

| 800 | 120 | 950 | 905 | 880 | 2400 | 16-27 | 800 | 150 | 950 | 905 | 898 | 2400 | 16-27 | ||

| 900 | 120 | 1050 | 1005 | 980 | 2800 | 20-30 | 900 | 150 | 1050 | 1005 | 998 | 2800 | 20-30 | ||